Our Story

Hallagan has been a family owned and operated company for over 100 years. We pride ourselves on not only our detailed craftsmanship, but on the people who have worked tirelessly to create ideal furniture solutions for our customers over the years.

The Beginning

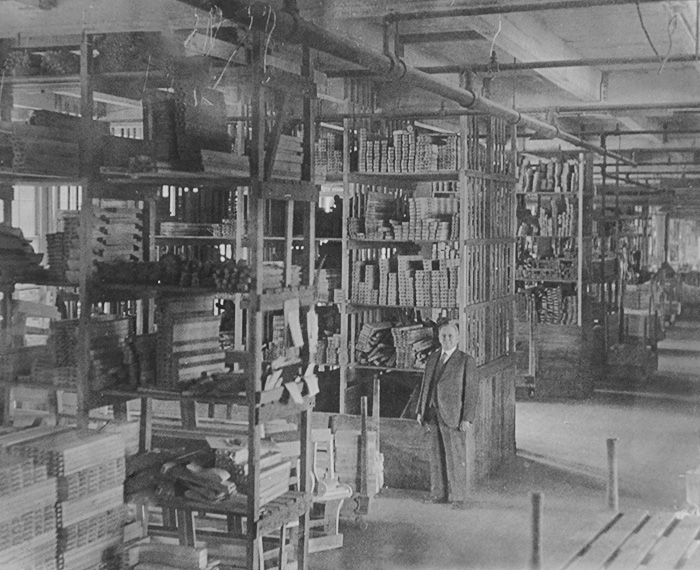

Hallagan Furniture has been making upholstered furniture since 1899 starting in Canastota, NY, just east of Syracuse. Simon Hallagan, with his partner Thompson, were finding success, and decided to move the company to Newark, NY, in 1913 to the old Mora car plant, which was out of business and lying empty. To this day, the saw dust collection ductwork in the rough mill bears the name “Canastota Couch Company.”

A Successful Operation

The company did well in the years under Simon’s leadership. While the depression was hard on everyone, the company decided to cut hours across the board in lieu of layoffs, to ensure each employee received some income. During WWII, to help the war effort, the production shifted to make sleeping bags for the Navy.

Simon’s sons, Stuart, Walt and Edwin Hallagan, took the company to the next level after the war and into the 1960’s, still focusing on special order custom upholstery for mid-to-high end living rooms. Stuart was at the helm, while Walt and Edwin played strong sales roles as they traveled throughout New York State.

The third generation of Charles and Richard Hallagan operated the company from the 1960’s to the mid 1990’s and established major territories in neighboring states by trucking upholstery deep into New England, the mid-Atlantic states and Ohio.

That Brings Us to Today

Today, Steve and Walt Hallagan have the privilege of leading the company in its fourth generation. As always, our team is our most valued resource. Collectively, our employees average 15 years of experience, some with as many as 50 years in the industry. They are highly skilled workers in all departments, including, fabric cutting and sewing, wood cutting, frame building, foam and fiber cushion fabrication, CAD design and trucking.

Investments in technology have improved our fabricating methods overall. Modern CNC computer based systems drive our fabric and wood cutting with unparalleled precision. Complete frames are cut and built on demand, eliminating the need to inventory hundreds of parts. Singer Machines, the vaunted sewing machines of the last century, have been replaced with the digitally driven “smart” models with automatic features for labor saving and better sewing quality. Our fiber blowing equipment is used to make back pillow inserts and bolster pillows.

The new technology has allowed us to dramatically change our offerings. But, as always, we continue to create upholstery made personal.